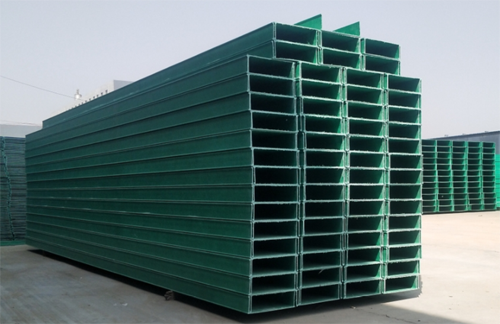

Fiberglass cover plate

Fiberglass cover plates are essential components used in various industries for their durability, strength, and versatility These cover plates are designed to provide protection, insulation, and aesthetic appeal to different structures and equipment

Fiberglass cover plates are essential components used in various industries for their durability, strength, and versatility. These cover plates are designed to provide protection, insulation, and aesthetic appeal to different structures and equipment. In this article, we will explore the production process of fiberglass cover plates and discuss their purpose in different applications.

Production Process:

The production of fiberglass cover plates involves a series of steps to create high-quality, customized products that meet the specific requirements of different industries. Here is an overview of the production process:

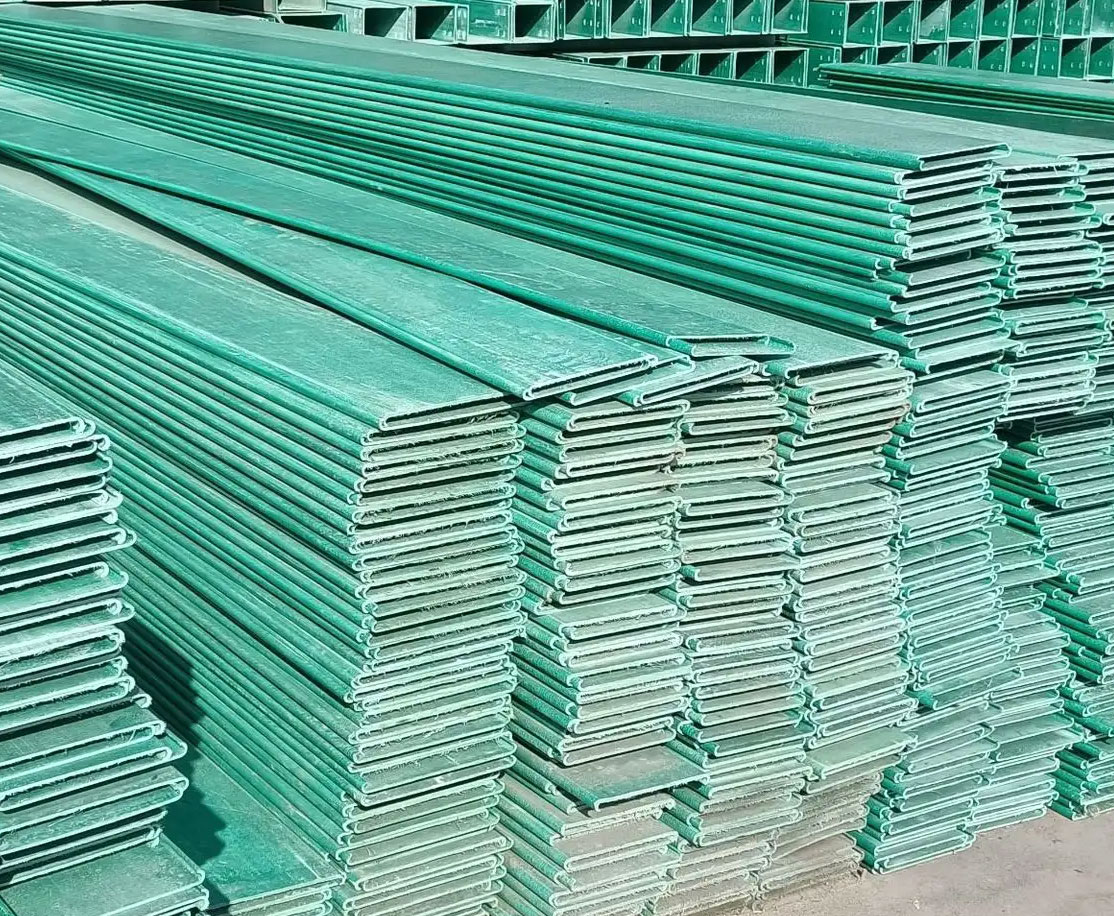

Material Selection: The production process begins with the selection of high-quality fiberglass materials, including fiberglass mats, resin, and additives. Fiberglass mats are typically made of woven glass fibers that provide strength and reinforcement to the cover plates. Resin acts as a binding agent that holds the fibers together and forms a solid composite structure.

Molding: Once the materials are selected, they are placed in a mold that is designed to the desired shape and size of the cover plate. The fiberglass mats are layered in the mold, and resin is applied to saturate the fibers and create a uniform composite structure. The mold may be heated or pressurized to facilitate the curing process and ensure the proper formation of the cover plate.

Curing: After the resin is applied, the cover plate undergoes a curing process to harden the material and solidify the composite structure. Curing may involve the application of heat, ultraviolet light, or chemical catalysts to accelerate the curing process and achieve the desired properties of the cover plate, such as strength, flexibility, and resistance to environmental factors.

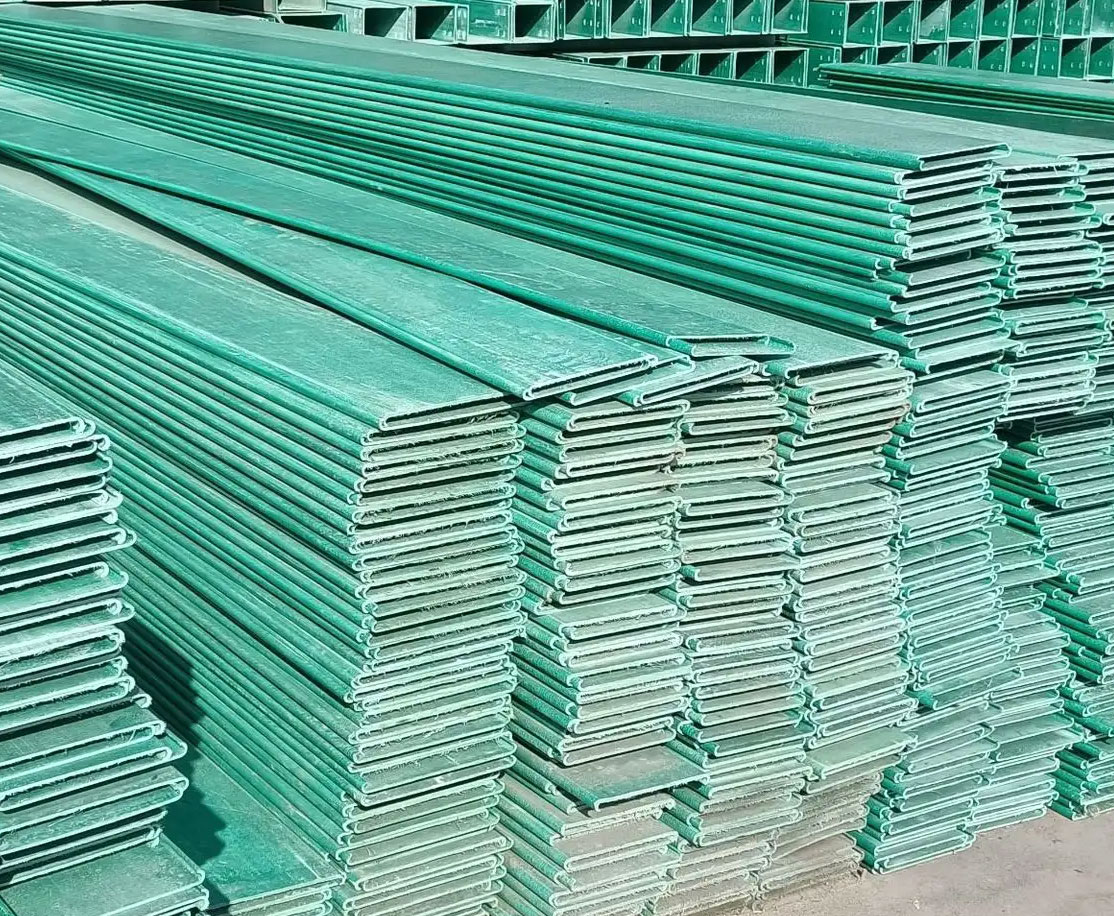

Finishing: Once cured, the fiberglass cover plate is removed from the mold and undergoes finishing processes such as trimming, sanding, and painting to achieve the desired appearance and surface texture. Additional treatments may be applied to enhance the cover plate's resistance to UV radiation, chemicals, and abrasion, depending on the intended application.

Quality Control: Before the cover plates are ready for use, they undergo rigorous quality control inspections to ensure that they meet industry standards and specifications. The cover plates are tested for strength, flexibility, durability, and other performance metrics to guarantee their reliability and longevity in different applications.

Purpose of Fiberglass Cover Plates:

Fiberglass cover plates serve a variety of purposes in different industries and applications due to their durability, versatility, and customizable features. Here are some key purposes of fiberglass cover plates:

Protection: Fiberglass cover plates are used to protect equipment, machinery, and structures from environmental elements, impact damage, and wear and tear. These cover plates provide a protective barrier that shields sensitive components from dust, moisture, and other contaminants, extending the lifespan of the equipment and ensuring its optimal performance.

Insulation: In electrical and thermal applications, fiberglass cover plates are used to provide insulation and temperature control. These cover plates have excellent thermal resistance properties, making them ideal for applications that require protection against high temperatures, electrical conductivity, and heat transfer.

Aesthetic Enhancement: Fiberglass cover plates are often used for aesthetic purposes to improve the appearance of structures, equipment, and architectural elements. These cover plates can be customized in various colors, shapes, and textures to complement the design aesthetics of different environments and create a visually appealing finish.

Corrosion Resistance: Fiberglass cover plates are resistant to corrosion, rust, and chemical degradation, making them suitable for outdoor and industrial applications where exposure to harsh environments is common. These cover plates provide long-lasting protection against corrosive substances, UV radiation, and weathering, ensuring the durability and integrity of the equipment or structure.

In conclusion, fiberglass cover plates are essential components used in a wide range of industries for their durability, versatility, and protective properties. The production process ensures that these cover plates meet the specific requirements of different applications, providing reliable solutions for protection, insulation, aesthetics, and corrosion resistance. Whether in industrial facilities, construction sites, or architectural projects, fiberglass cover plates play a crucial role in enhancing the performance, longevity, and appearance of str